1. In what situations do the best ideas arise?

In his excitement, he ran naked through Syracuse shouting, “Eureka!” (“I have found it”). He got his best idea while taking a bath. The mathematician Archimedes of Syracuse (287-212 BC) was tasked by King Hieron II to determine whether his crown was made of pure gold. He discovered the answer through water displacement, leading to the “Archimedean principle”.

The best ideas come while showering, walking, and upon waking. Suddenly, they are there. But where do they come from? From the subconscious! How did they get there? Often, it is a problem that has not let go of us, one that continues to occupy our subconscious even at night.

Then comes that moment: the urgent problem and the selection of possible solutions come together and fit just perfectly.

The crucial question is: How did they get there—into the subconscious of those who know the solutions?

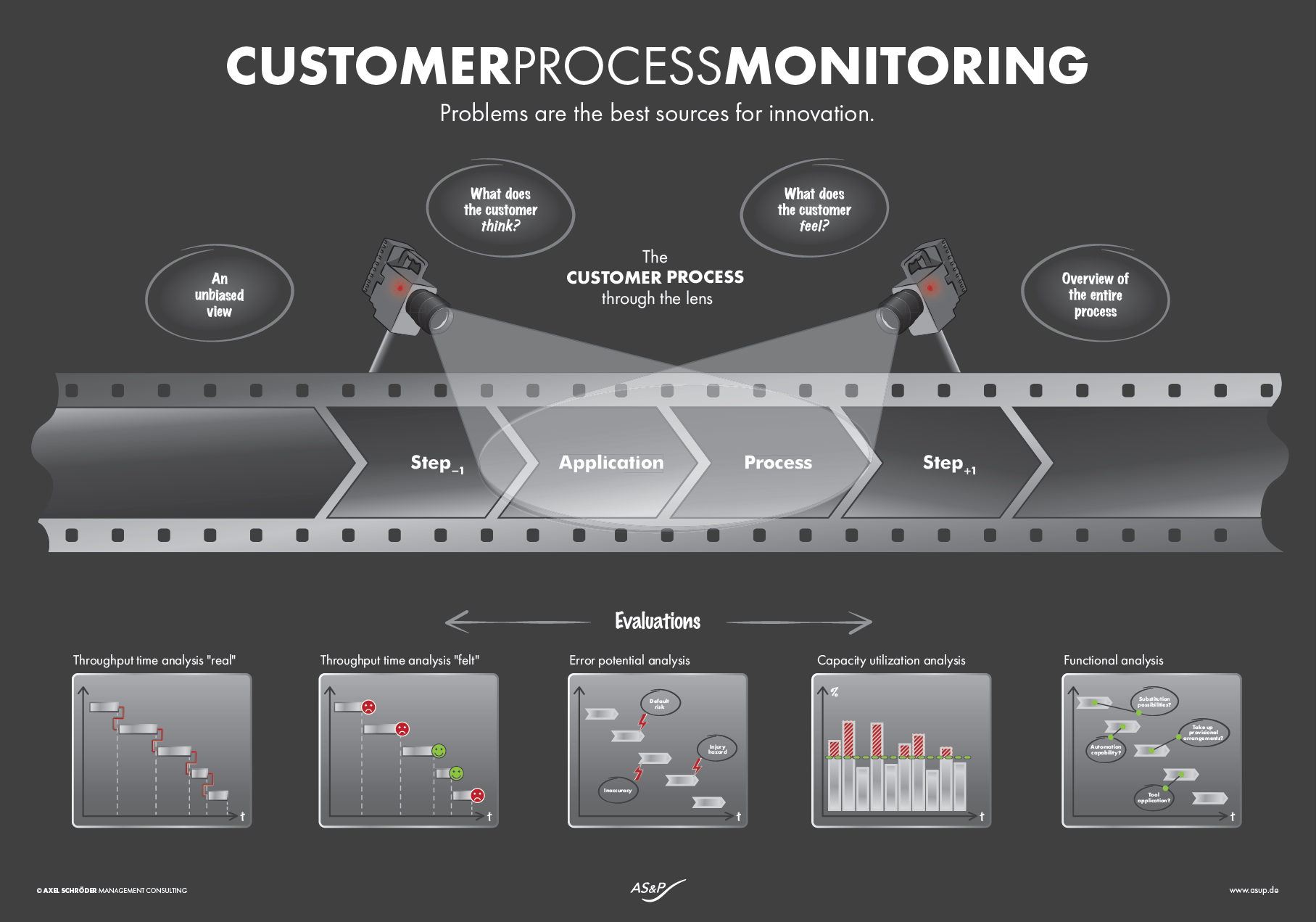

CUSTOMERPROCESSMONITORING.

2. The problem is more important than the solution.

How do we find – systematically – the right problem?

When we look for new solutions with engineers in an innovation workshop, they draw from an oversupply of possibilities. Generally, everything can somehow be technically solved. The question is with what complexity, at what cost, and in what time. The simple is the ingenious.

But even more important than the question of the QKT trilemma is the question of whether we are answering the right question. What use are answers to questions never asked?

We must ensure that we have correctly understood the practice, the application. What the customer really needs. And that is often not what the customer has already recognized and is already able to articulate. Because then he will surely not only reveal it to us but also to the competitors – and we are already in the time trap!

Moreover, such customer wishes are actually complaints that repair the past and do not shape the future.

CUSTOMERPROCESSMONITORING.

3. Where do we find the right problems?

We stood deep in the mud with our rubber boots. In one hand, our camera. In the other hand, a stopwatch. We observed garden and landscape builders at their work. They had procured a heavy metal weight from the junkyard, with three handles welded onto it. Three of them lifted the weight and let it fall onto a wooden post, driving it centimeter by centimeter deeper into the ground. They were anchoring planting trees with posts. This was in this millennium – not in the Middle Ages!

This was just one example of many makeshift solutions, laborious tasks, and processes prone to high error rates that we could observe. We then analyzed a representative number of construction sites using all the possibilities of modern process analysis. This resulted in quantitative throughput time analyses, FMEAs (Failure Mode and Effects Analyses), capacity analyses, but also stress analyses (how easy or difficult the work is). The most important was the video material. With it, we were able to bring our findings into the hallowed halls of R&D. No one there in the lab could have imagined what we had really experienced in practice.

We do not find the right problems in the lab but where the application takes place.

CUSTOMERPROCESSMONITORING.

4. The developer develops.

With the extract of the insights gained from practice, the idea of the motorized pile driver was born in an innovation workshop. A week later, we had the prototype in our hands. Market analysis revealed a huge potential in terms of quantity because many fences are built in this world. Many of them also need to be moved repeatedly. A new, very lucrative business area was successfully established.

Couldn’t one have come up with this idea without CPM? Why must the practical application be brought into development first? Why don’t developers regularly go out into the field? The answer is simple: because developers usually have more tasks than they can manage. Because an R&D department is usually tasked with more projects than it has capacity for. Every free minute is precious for catching up on delays and meeting schedules. The developer develops.

“The developer should spend much more time in practical application” will always remain a pious wish.

However, professional CPM analyses are also not his core competence.

CUSTOMERPROCESSMONITORING.

5. The treasure chest.

Companies that have once recognized the potential in the systematic analysis of application processes want to repeat these successes.

DRAEGER, a market leader in medical and safety technology, has made it a requirement that a CPM analysis be presented before any budget approval for a development project.

FESTOOL, the brand for professional power tools, has built a CPM database. In it, one can sort by application processes, analyze problem areas with numbers, data, and facts, and get an objective feel for how users really work through on-demand video analyses in a very short time.

VIEGA systematically pursues the strategy of moving from a product provider to a solution provider. Installers were observed with CPM while installing bathroom fittings. This was the basis before they built a new product area with a well-thought-out platform architecture.

In strategy workshops, the question of core competence is asked. In which technological fields are we unique? The answer is often: “Actually, in every technology in this world, there is someone else who can also do it. But we understand the customer better! That is our true core competence. To not leave this competence to chance, we use CPM. We have created a database for this. It is the treasure chest from which we can always draw and bring ourselves to an objective state when we start a new product development.”

CUSTOMERPROCESSMONITORING.

Self-Assessment Workshop

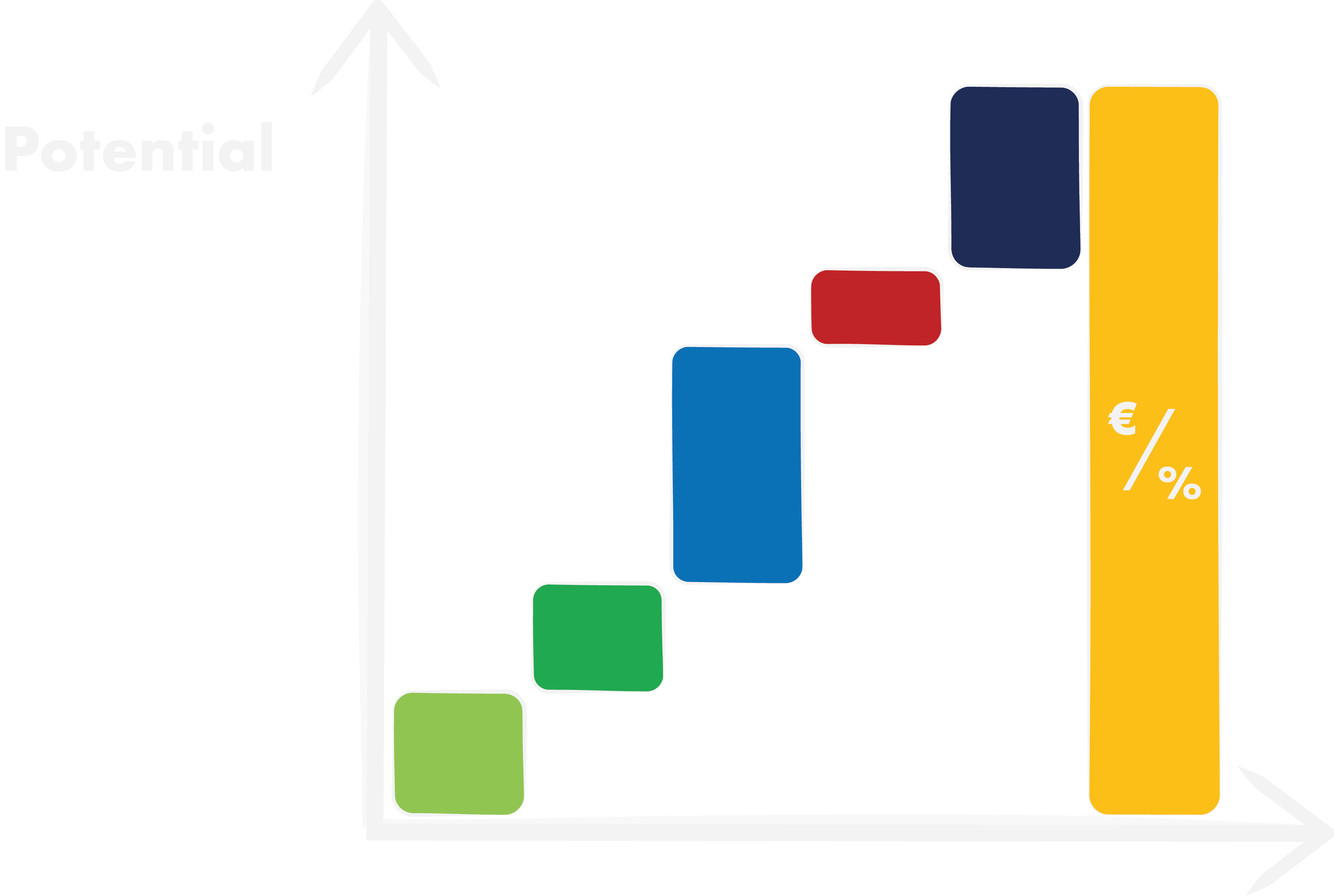

Improvement Potential

Assessing

CPM Potential.

The success of implementing CPM must be evaluated on a company-specific basis:

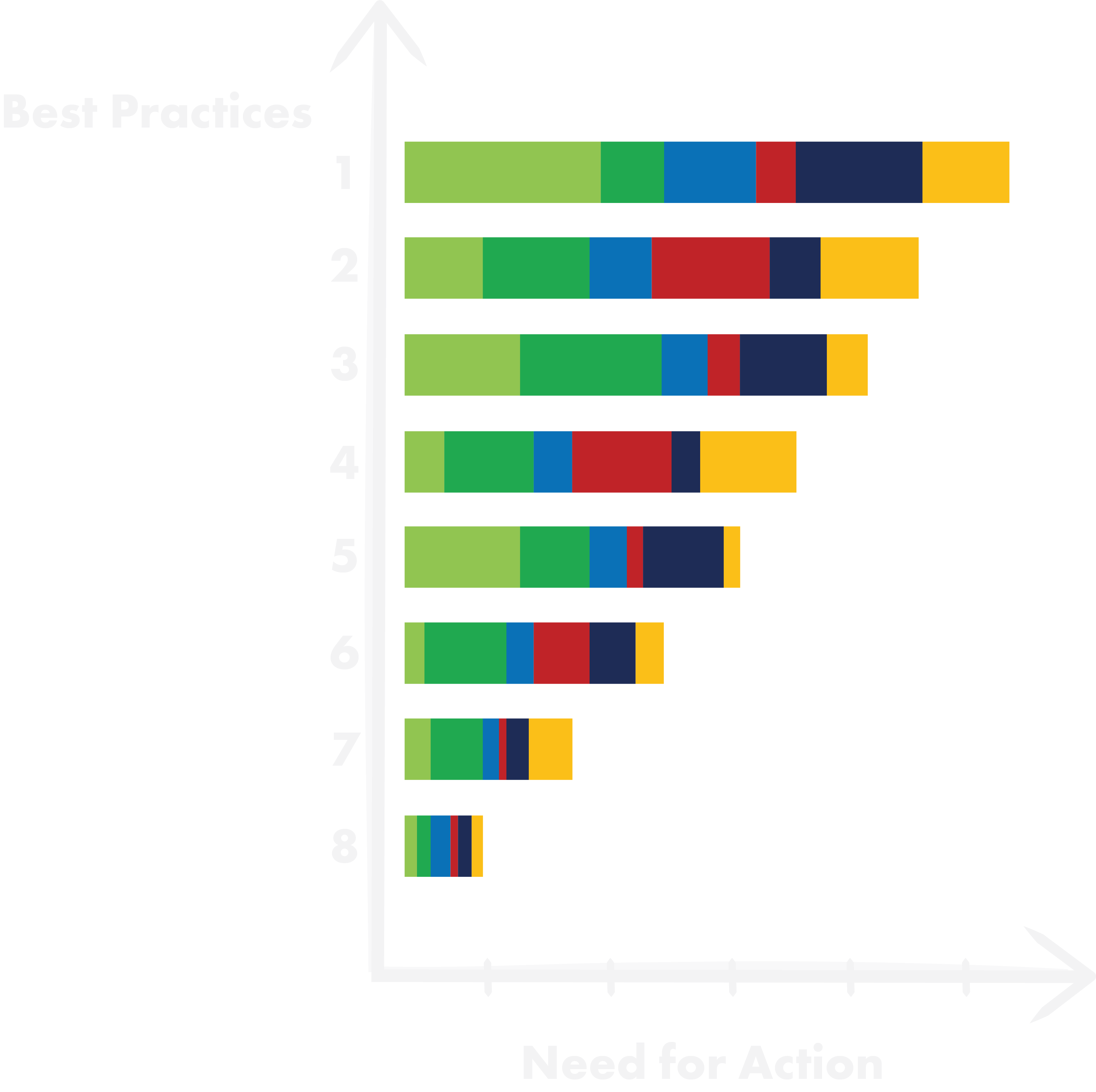

1. Current State Analysis.

– First, we want to understand your current situation.

2. Self-Assessment-Workshop.

– In the self-assessment workshop, we will show you best practices.

3. Action Plan.

– Based on this, you assess your need for action.

4. Improvement Potential.

– We estimate the quantitative improvement potential.

5. Vision.

– Together, we define a vision.

6. Implementation Plan.

– We establish an implementation plan.

We estimate your R&D performance.

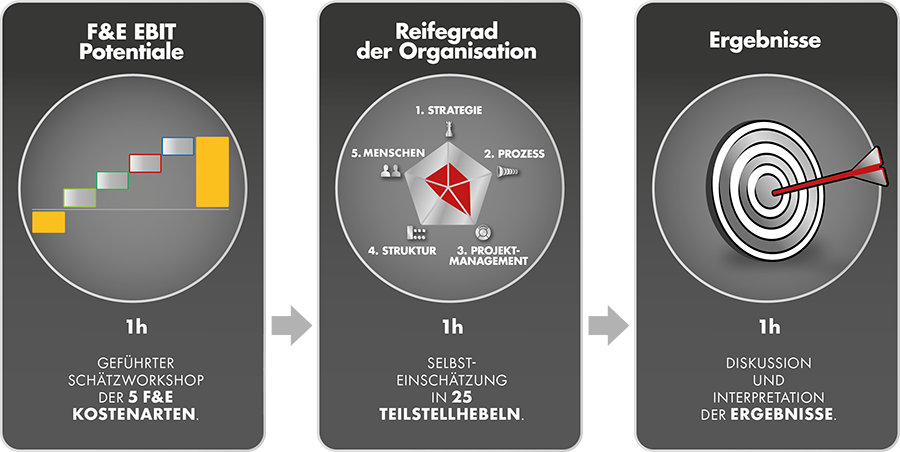

The R&D Performance Self-Assessment.

In a 3-hour workshop with the R&D leadership team, you will learn about our methodology:

Part 1: Self-assessment of R&D EBIT cost potentials.

Part 2: Maturity level of the organization across 5 levers.

Part 3: Result interpretation.

By narrowing down through scenarios, it quickly becomes clear whether an initiative is worthwhile.