1. Where are the nuggets?

It doesn’t make much sense to start with the “peanuts”. What proportion of the product has the highest manufacturing cost share?

The ranking of assemblies and components of the product, ordered by the magnitude of their material costs, is the starting point – value analysis. But beware! – Material costs are only half the story. C-parts have the lowest material costs but incur expenses in procurement, incoming goods inspection, storage, and possibly minimum order surcharges. The actual process costs often exceed the material value by multiple times.

PRODUCTCOSTDOWN.

2. What is it worth to the customer?

If we were to proceed top-down based on this ranking now, meaning to reduce the assemblies and parts with the highest process costs through more creative design solutions, then we would miss out on an opportunity. Namely, the opportunity to align the functionality of the product more closely with the customer. That is precisely the goal of function-cost-value analysis.

We assess the functions of the product based on their utility to the customer. The components and assemblies of the product involved in a highly valued function are given significant weighting. Assemblies with a high value contribution may even be allowed to become more expensive. Assemblies with the lowest value contribution should be reduced, ideally eliminated.

This makes the product more valuable – not just cheaper. The greatest impact of this exercise is the new perspective it provides. This enables even the “fathers” of the product to view their work from a new angle.

PRODUCTCOSTDOWN.

3. Design smarter.

Fewer parts, but more integrated, a product concept that is easier to manufacture and assemble more quickly. Cheaper materials without sacrificing quality, that’s what we’re aiming for.

The question is, how do we get there?

“For years, we simmered in our own juices, but external stimuli worked wonders! Combined with a systematic and methodical approach, we were able to overcome self-imposed limitations that had developed over years. Particularly helpful was consistent product benchmarking, not only with competitor products but also with technical solutions from distant fields.

AS&P has a network built over 30 years in the industry. Direct expert exchanges with other companies, focusing on predefined topics, opened up new horizons for us.

Applying creativity techniques was really enjoyable. For example, the headstand method, where we sought the opposite: how could the solution become maximally “expensive”? Surprisingly, this approach enabled us to find the path to a cost-effective solution.”

If an idea doesn’t initially seem absurd, then it’s probably not worth pursuing. (Albert Einstein)

PRODUCTCOSTDOWN.

4. Quick successes.

Nothing motivates more than success!

The “Design thinking” method, with its steps: 1. Empathize, 2. Define, 3. Ideate, 4. Prototype, and 5. Test, is not only incredibly fast but also extremely effective.

Originally intended for ideation processes to create completely new innovations and products, the method requires even more creativity in the product-cost-down process due to tighter constraints.

In 1. Empathize, one deeply empathizes with the customer or user. You walk in the customer’s shoes. A “persona” is defined, a quasi-virtual person with the collected characteristics of the typical customer. The insights gathered in this phase are prioritized, evaluated, and focused on in Phase 2. Define. In Phase 3: Ideate, creativity techniques mentioned earlier are applied, deliberately expanding the range of solutions. In Phase 4: Prototype, one idea is chosen and quickly implemented. Technological methods like Rapid Prototyping and 3D printing offer new possibilities. In Phase 5: Test, the prototype is shown to real pilot customers to gather rapid feedback. The process is iteratively repeated multiple times.

Early and swift feedback leads to fast and assured successes.

PRODUCTCOSTDOWN.

5. Highly motivated teams.

Admittedly, the challenge is not easy. Improving an existing product together with the people who themselves developed it. It’s all too human to defend the existing solution, unconsciously blocking better alternatives. How can this be achieved nonetheless?

The most important factor is voluntariness. People working in a Product-Cost-Down team have applied for this project voluntarily. Typically, we have more applicants than available positions, ensuring that these individuals are truly enthusiastic about it.

But this can be enhanced further with a booster: When multiple teams engage in competitive sports on the same task, motivation reaches its boiling point. Few things spur more ambition, focus, energy, and motivation than competitive sports. Caution! Not every corporate culture allows for this.

The moderator’s primary task is to create a framework that fosters psychological safety.

PRODUCTCOSTDOWN.

Self-Assessment Workshop

Improvement Potential

Assessing PRODUCTCOSTDOWN Potential:

1. Current State Analysis.

– First, we want to understand your current situation.

2. Self-Assessment-Workshop.

– In the self-assessment workshop, we will show you best practices.

3. Action Plan.

– Based on this, you assess your need for action.

4. Improvement Potential.

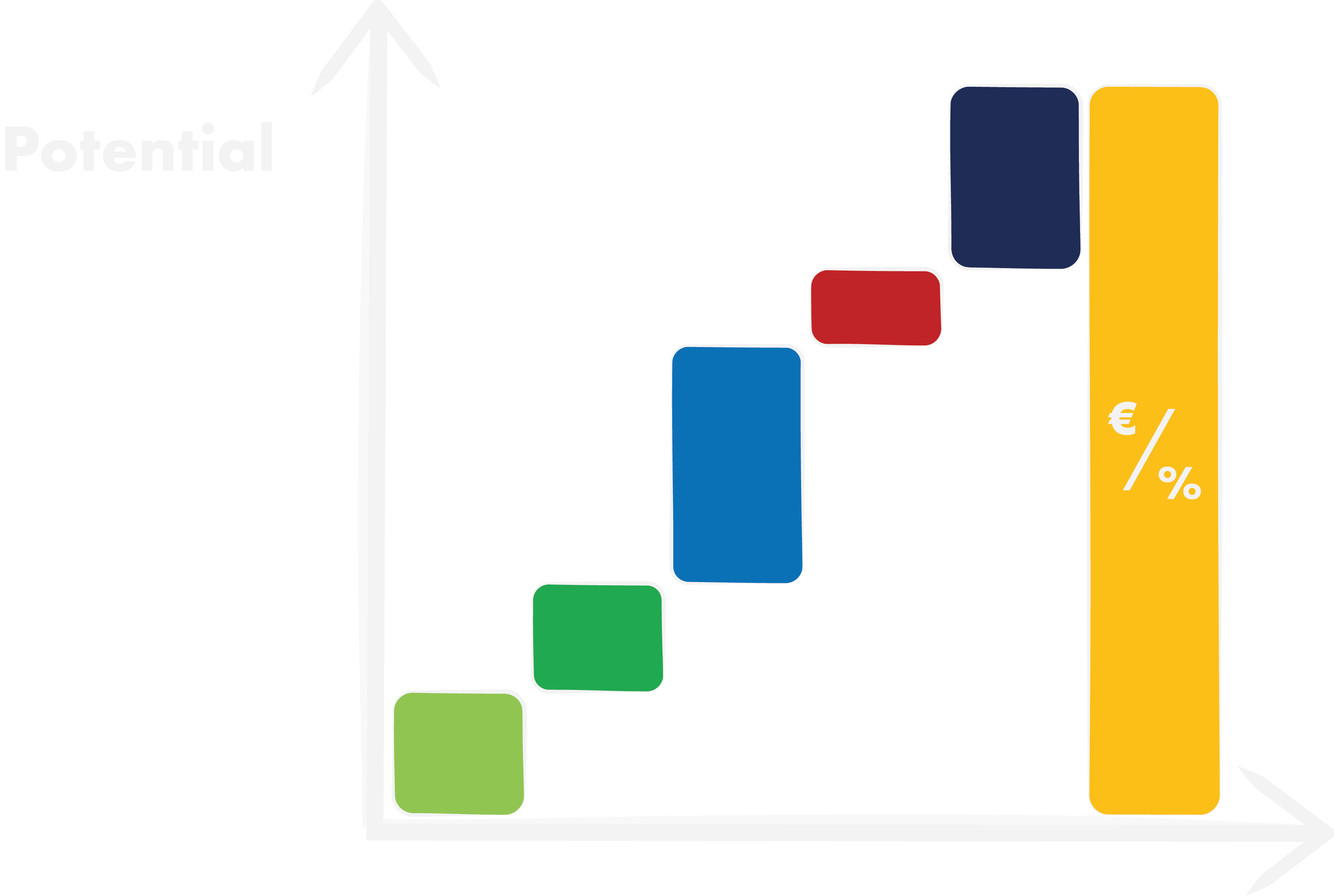

– We estimate the quantitative improvement potential.

5. Vision.

– Together, we define a vision.

6. Implementation Plan.

– We establish an implementation plan.

We estimate your R&D performance.

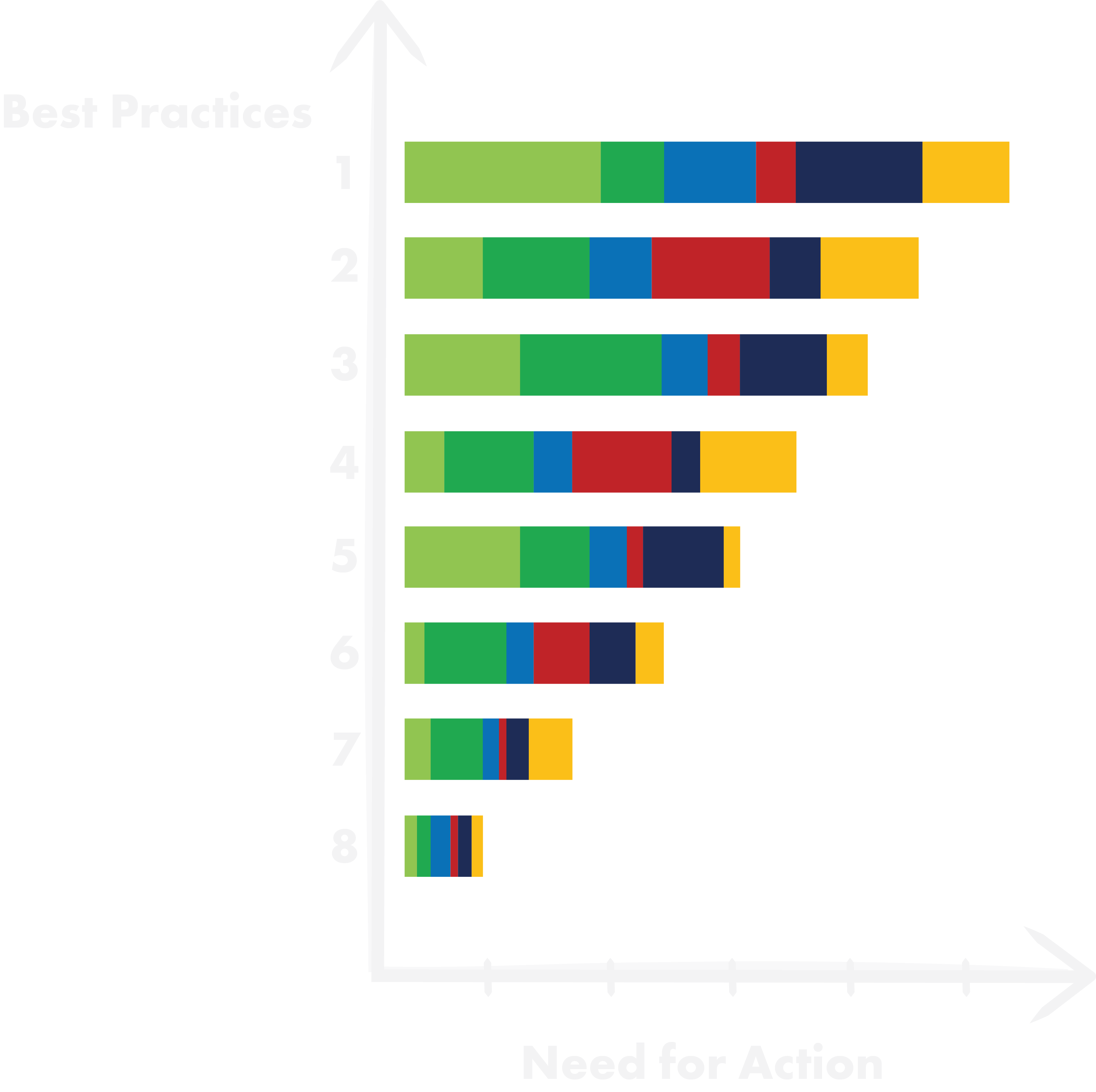

The R&D Performance Self-Assessment.

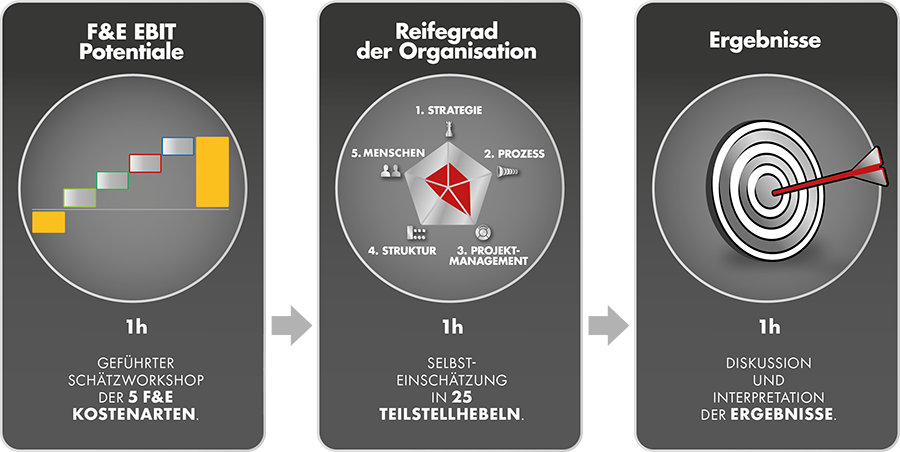

In a 3-hour workshop with the R&D leadership team, you will learn about our methodology:

Part 1: Self-assessment of R&D EBIT cost potentials.

Part 2: Maturity level of the organization across 5 levers.

Part 3: Result interpretation.

By narrowing down through scenarios, it quickly becomes clear whether an initiative is worthwhile.