1. Pipeline overloaded?

A plant manager has an order intake of 30%. Let’s imagine the plant has ideal conditions in its production processes. All orders would flow through the plant without friction losses, in the ideal flow state. At 30% input – what would the output be?

Correct: 30%.

Now, let’s assume the plant manager is lucky. Exactly 100% order intake and again ideal flow conditions. What would the output be now?

Correct: 100%.

Now, the order intake increases to 130%. What is the output now?

Not 100% – but 80%! Why?

Now the plant enters turbulence. Orders obstruct each other. Customers exert pressure. Orders need to be expedited. Others need to be halted. Machines need to be reconfigured. Orders wait. Production capacity is wasted.

What applies to the plant also applies to development. In development, machine setup times are the mental setup times of developers. For highly complex tasks, an expert needs at least 2 hours to interrupt a task in such a way that they can build upon it later, and additional time to delve into the even more important task.

Two reprioritizations per day equate to 50% of working time.

Pipeline overloading is not a minor offense – it destroys capacity!

TIMEBOXEDR&D

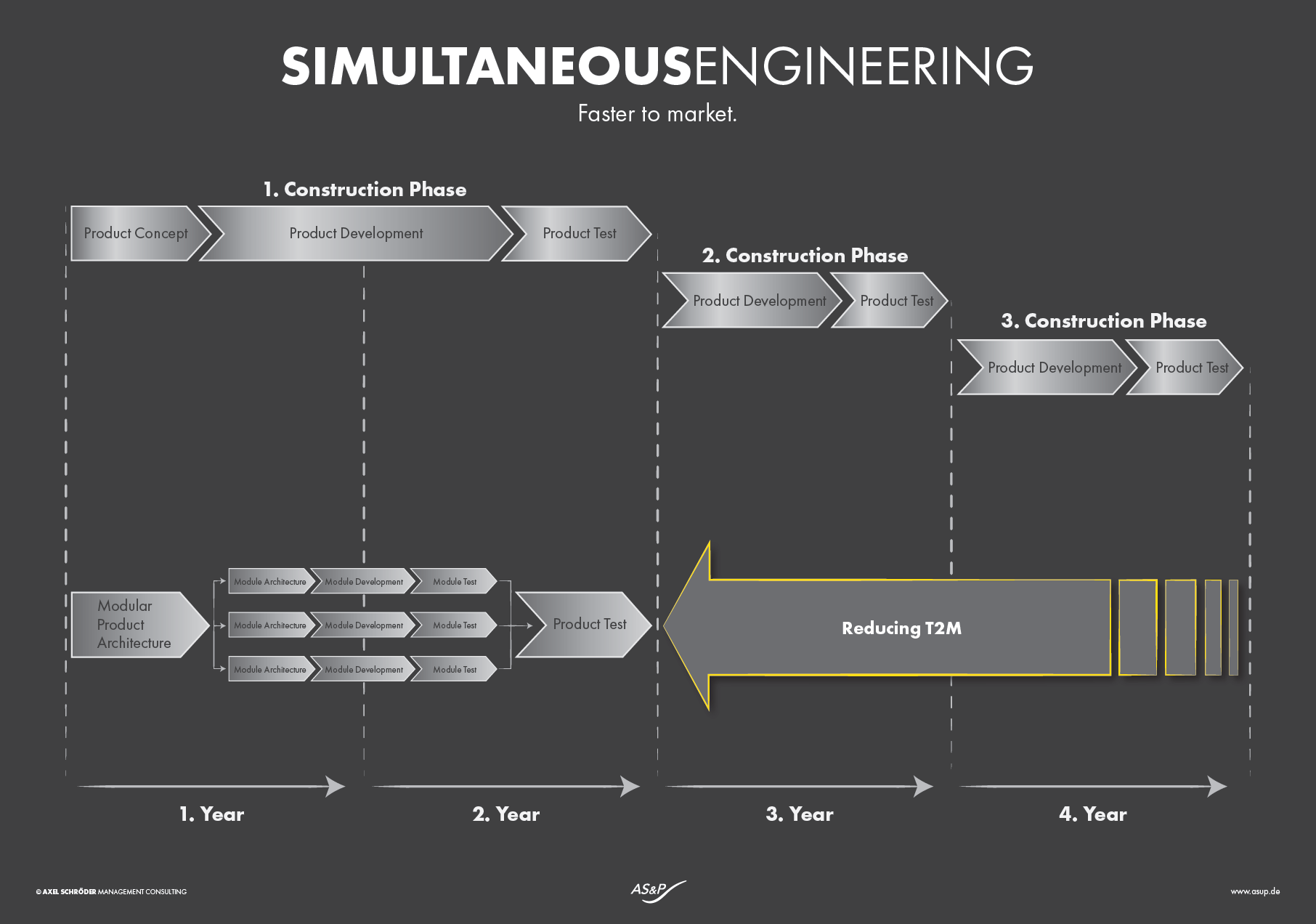

2. On-time delivery before T2M?

If you had to decide, what is more important to you: Shorter development times or the punctuality of development projects?

If development projects then enter series production when production has prepared everything for it, lead times could be halved.

If sales could time the market launch so that global introduction could be synchronized, ramp-up would be shortened and revenue would come earlier.

This increases the company’s EBIT rate.

The question is, how to achieve higher predictability and punctuality of development projects?

TIMEBOXEDR&D

3. The “tankless water heater” principle.

What is the most common reason for Cost of Delay? Too high technical risks. Too many development loops.

Companies with too little pre-development capacity have too high technical risks in their series development projects.

Pre-development has the task of filtering out these technical risks and reducing them in advance. The “sacred” capacity of series development becomes more predictable and reliable.

The big danger in building up pre-development is that it becomes an ivory tower. Then what comes out of pre-development is not accepted by series development. “Happy engineering” develops technologies that series development does not need. The not-invented-here syndrome strikes.

The “tankless water heater” principle achieves an optimal transition from pre-development to series development. Pre-development is strategically led by a small, experienced core team. Employees go through the entire process from idea to series launch.

No separation – no interface.

TIMEBOXEDR&D

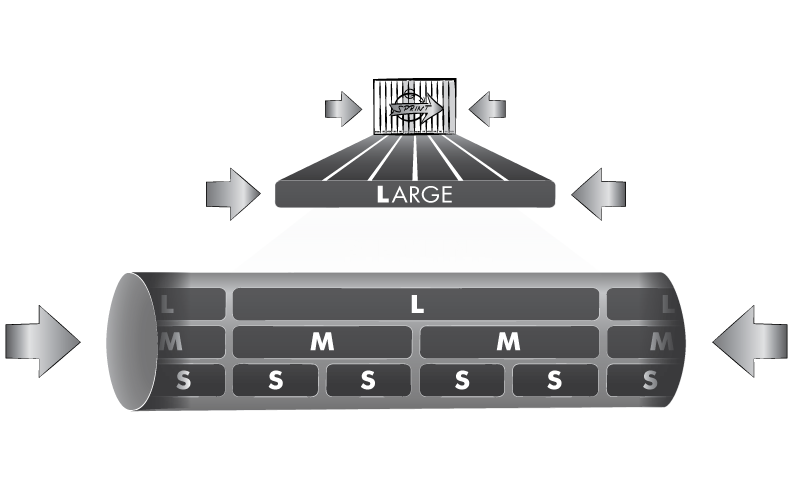

4. Project classes.

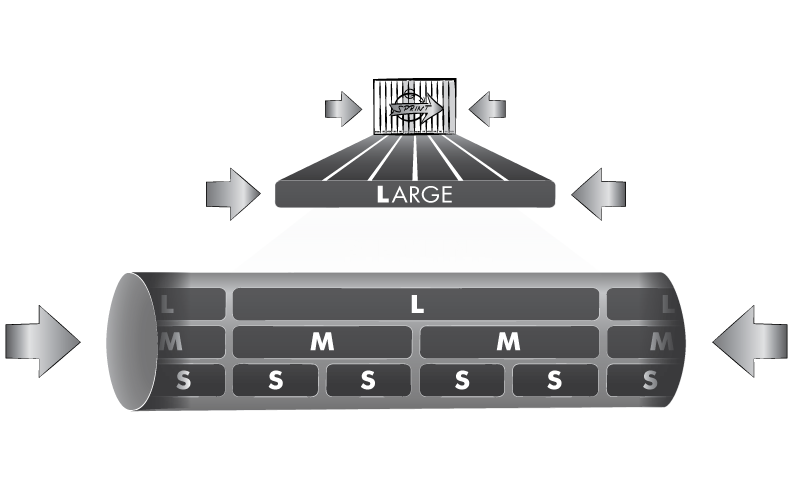

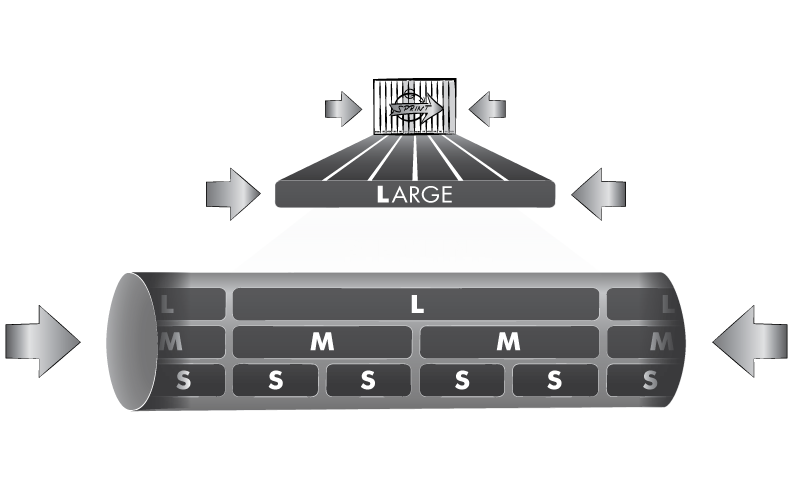

A pipeline flows faster and more smoothly when the flow medium is more homogeneous.

The flow through the R&D pipeline accelerates when the project sizes are less varied.

Imagine dividing your development projects into defined project classes: Small, Medium, and Large. You can then assign your employees to more manageable or complex projects based on their experience and expertise. This allows employees to improve their performance within these stages.

Standardization and optimization can be implemented within the defined project classes.

This leads to higher performance.

TIMEBOXEDR&D

5. Time boxing.

In the AGILE approach, we no longer ask: How long do we need for which complexity? Instead, we ask: How much complexity can fit into a 2-week sprint? That’s timeboxing.

Timeboxing is the prerequisite for us to establish repetition despite all the unpredictability that innovation brings. We repeat 2-week sprints. The brain learns through repetition. Synapses form. Trails become highways. We cannot avoid becoming better at estimating the workload for a 2-week sprint. This makes us more confident. We gain more self-assurance. Confident people are more courageous, they dare more and achieve more. This is a fundamental basis for higher performance in R&D.

With the TIME-BOXED-R&D approach, we apply the concept of timeboxing from sprints to the entire project.

The timebox for the 2-week sprint becomes a timebox for the entire project duration.

This requires prerequisites:

1. Pipeline load is regulated through a heatmap.

2. The risk of unforeseen technical surprises is reduced through pre-development.

3. The project portfolio is managed using a mix of defined project classes.

The flow velocity in the pipeline increases.

Project deadline adherence improves.

TIMEBOXEDR&D

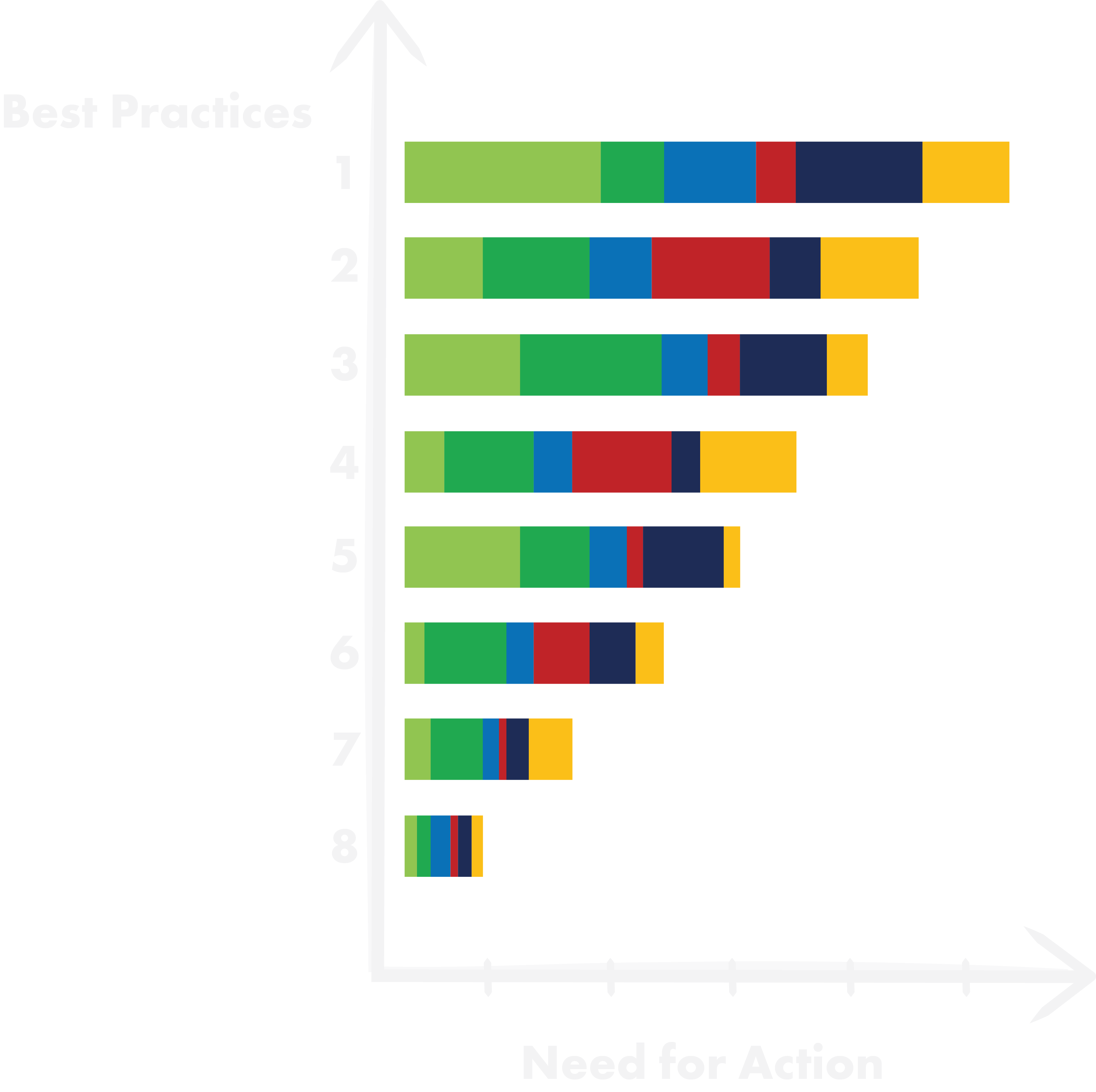

Self-Assessment Workshop

Improvement Potential

Assess TIMEBOXEDR&D Potential.

1. Current State Analysis.

– First, we want to understand your current situation.

2. Self-Assessment-Workshop.

– In the self-assessment workshop, we will show you best practices.

3. Action Plan.

– Based on this, you assess your need for action.

4. Improvement Potential.

– We estimate the quantitative improvement potential.

5. Vision.

– Together, we define a vision.

6. Implementation Plan.

– We establish an implementation plan.

We estimate your R&D performance.

The R&D Performance Self-Assessment.

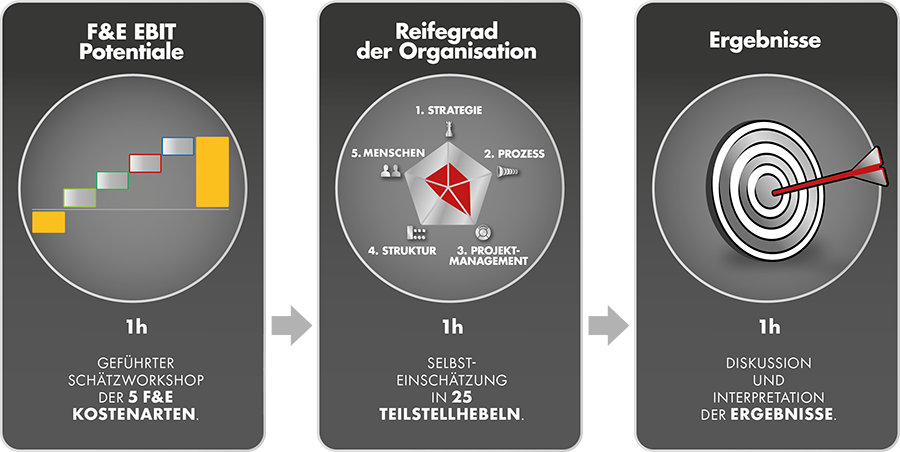

In a 3-hour workshop with the R&D leadership team, you will learn about our methodology:

Part 1: Self-assessment of R&D EBIT cost potentials.

Part 2: Maturity level of the organization across 5 levers.

Part 3: Result interpretation.

By narrowing down through scenarios, it quickly becomes clear whether an initiative is worthwhile.